Best Jack Stands for Cars: Safe Lifting and Vehicle Support Guide

Picture this: you’re under your car changing the oil when suddenly you hear a metallic groan. Your heart stops as you realize you’ve been trusting your life to a wobbly old jack that’s seen better days. Don’t let this nightmare become reality – investing in quality automotive jack stands isn’t just about convenience, it’s about protecting your most valuable asset: your life. Every year, countless DIY mechanics put themselves at risk by using inadequate or damaged lifting equipment. The difference between a safe garage session and a tragic accident often comes down to one crucial piece of equipment: a reliable jack stand. Whether you’re a weekend warrior tackling brake jobs or a daily driver who wants to rotate tires safely, understanding how to choose and use the right car jack stands can save both your life and your money.

Key Takeaways

• Safety first: Quality jack stands are essential for any under-car work – never rely on a floor jack alone • Weight capacity matters: Choose jack stands rated for at least 25% more than your vehicle’s weight per axle • Proper placement: Always use jack stands on solid, level ground and position them on designated lift points • Regular inspection: Check your stands before each use for cracks, bent components, or worn locking mechanisms • Work in pairs: Use multiple jack stands and never work under a car supported by just one stand

• Safety first: Quality jack stands are essential for any under-car work – never rely on a floor jack alone • Weight capacity matters: Choose jack stands rated for at least 25% more than your vehicle’s weight per axle • Proper placement: Always use jack stands on solid, level ground and position them on designated lift points • Regular inspection: Check your stands before each use for cracks, bent components, or worn locking mechanisms • Work in pairs: Use multiple jack stands and never work under a car supported by just one stand

Why Every Car Owner Needs Quality Jack Stands

When it comes to vehicle maintenance, cutting corners on safety equipment is never worth the risk. A stand jack car setup provides the stable, secure foundation you need for any work that requires getting under your vehicle. Unlike hydraulic jacks that can slowly leak down or fail catastrophically, properly rated automotive jack stands offer mechanical support that won’t give way unexpectedly. Think of jack stands as insurance for your garage time. Just like you wouldn’t drive without proper tire maintenance, you shouldn’t work under your car without reliable stands. The peace of mind alone is worth the investment, but when you consider the alternative – potential injury or death – quality car jack stands become absolutely essential.

The Hidden Costs of Cheap Equipment

Many car owners make the mistake of buying the cheapest auto jack stands they can find, thinking they’re all basically the same. This couldn’t be further from the truth. Low-quality stands often feature:

- Weak welding that can fail under load

- Soft metals that bend or crack over time

- Poor locking mechanisms that slip unexpectedly

- Inadequate weight ratings for modern vehicles

Investing in quality automotive jack stands from the start saves money in the long run and, more importantly, protects your safety every time you slide under your car.

Types of Jack Stands: Finding Your Perfect Match

Not all car floor jack stands are created equal. Understanding the different types available helps you choose the right tool for your specific needs and vehicle type.

Not all car floor jack stands are created equal. Understanding the different types available helps you choose the right tool for your specific needs and vehicle type.

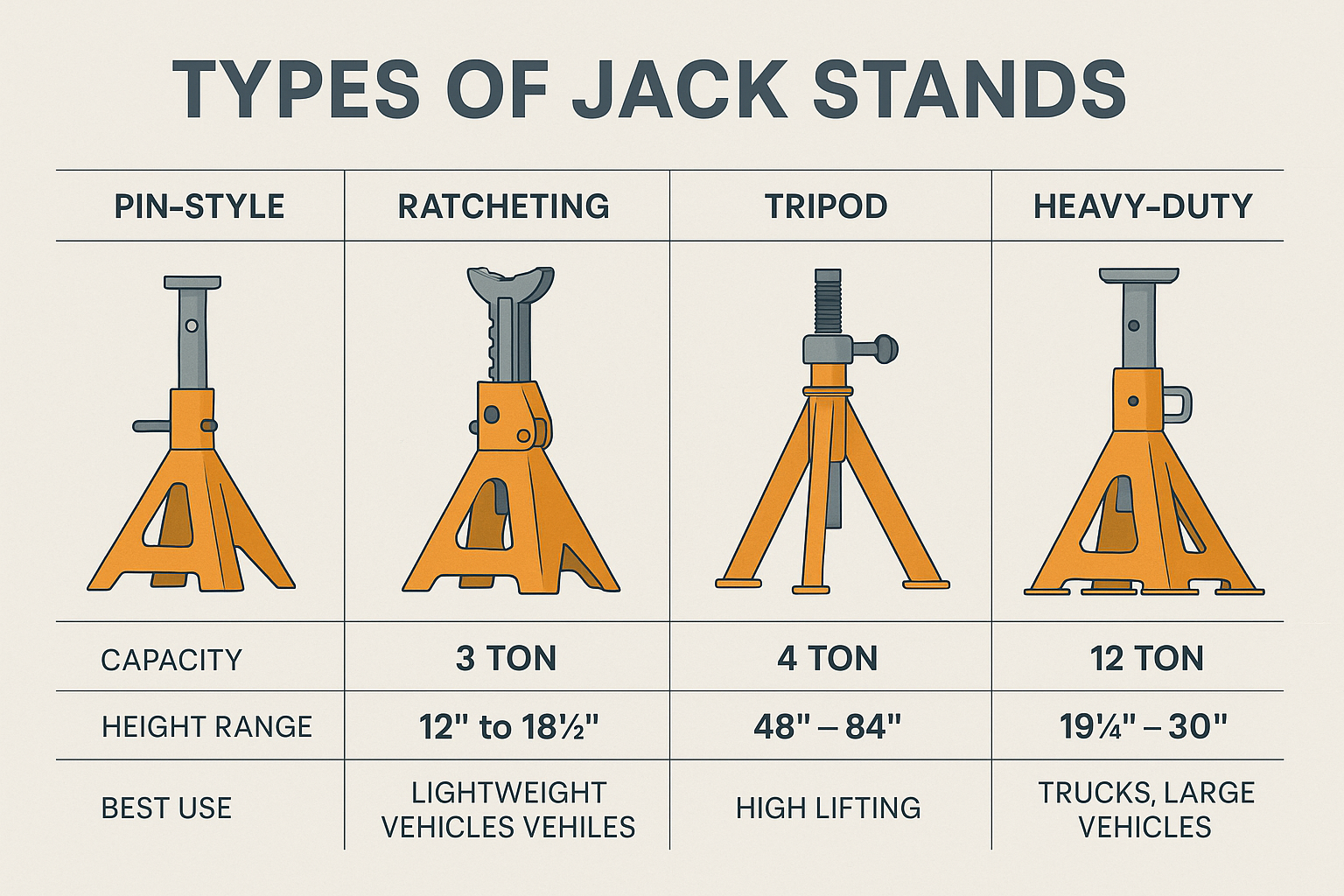

Pin-Style Jack Stands

Pin-style stands use a simple pin-and-hole system to lock the support post at your desired height. These are the most common type found in home garages because they’re:

- Affordable and reliable

- Easy to adjust with clear height markings

- Simple to inspect for wear and damage

- Available in multiple weight capacities

The main drawback is that height adjustments are limited to pre-drilled holes, which might not always align perfectly with your vehicle’s lift points.

Ratcheting Jack Stands

Ratcheting stands offer infinite height adjustment within their range, making them incredibly versatile. The ratcheting mechanism provides:

- Precise height control for any vehicle

- Quick adjustment without removing pins

- Secure locking with multiple engagement points

- Professional-grade stability

These tend to cost more than pin-style stands but offer superior convenience and adjustability.

Tripod Jack Stands

For vehicles with limited ground clearance or unusual lift point configurations, tripod stands provide excellent stability. Their three-leg design offers:

- Superior stability on uneven surfaces

- Compact storage when collapsed

- Easy positioning around vehicle components

- Excellent load distribution

Heavy-Duty Jack Stands

For trucks, SUVs, and commercial vehicles, heavy-duty stands are essential. These robust units typically feature:

- Higher weight capacities (6+ tons per stand)

- Reinforced construction with thicker steel

- Wider bases for enhanced stability

- Extended height ranges for lifted vehicles

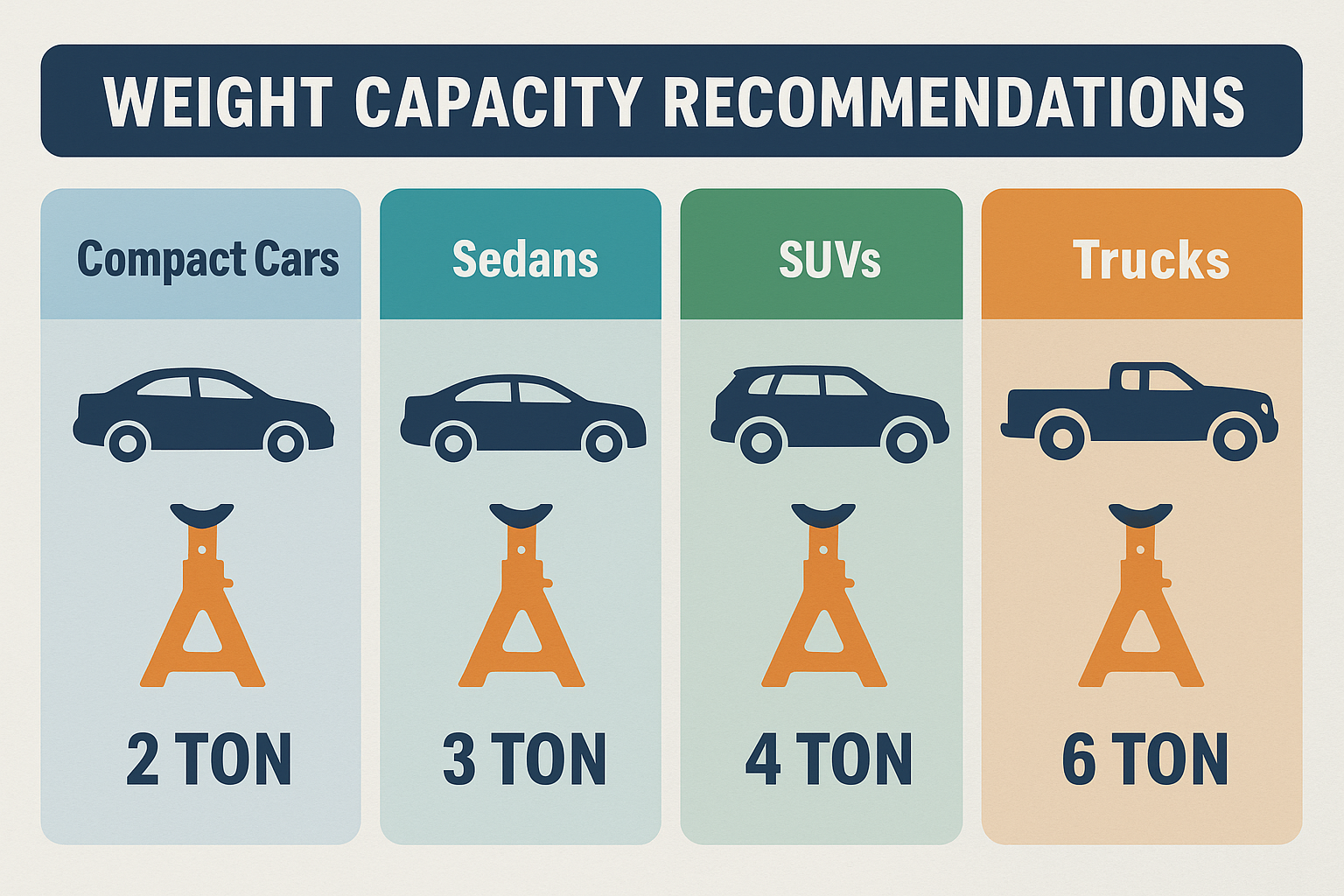

How to Choose the Right Jack Stand Capacity

Selecting the proper weight rating for your car stands and jack setup is crucial for safety. Many people underestimate how much weight each stand needs to support, leading to dangerous situations.

Selecting the proper weight rating for your car stands and jack setup is crucial for safety. Many people underestimate how much weight each stand needs to support, leading to dangerous situations.

Understanding Weight Distribution

When you lift one end of your car, the weight isn’t evenly distributed. The front and rear of most vehicles have different weight distributions:

- Front-heavy vehicles (front-engine cars): 60-65% of weight on front axle

- Rear-heavy vehicles (rear-engine sports cars): 55-60% of weight on rear axle

- Balanced vehicles (mid-engine, some trucks): 50-55% split

The 25% Safety Rule

Professional mechanics follow a simple rule: choose jack stands rated for at least 25% more than the maximum weight they’ll support. This safety margin accounts for:

- Dynamic loading during positioning

- Uneven weight distribution

- Manufacturing tolerances

- Wear over time

For example, if your car weighs 4,000 pounds and you’re lifting the front end (2,400 pounds), each of two jack stands should be rated for at least 1,500 pounds (2,400 ÷ 2 × 1.25 = 1,500).

Common Vehicle Weight Ranges

| Vehicle Type | Typical Weight | Recommended Stand Capacity |

|---|---|---|

| Compact Cars | 2,500-3,200 lbs | 2-3 ton stands |

| Mid-size Sedans | 3,200-4,000 lbs | 3-4 ton stands |

| Full-size Cars/SUVs | 4,000-5,500 lbs | 4-6 ton stands |

| Pickup Trucks | 4,500-7,000 lbs | 6-8 ton stands |

| Heavy-duty Trucks | 7,000+ lbs | 8+ ton stands |

Essential Safety Features to Look For

When shopping for automotive jack stands, certain features separate quality units from potentially dangerous knockoffs. Here’s what to prioritize:

Robust Construction Materials

Quality auto jack stands should be made from:

- High-grade steel (not cast iron, which can crack)

- Welded joints rather than bolted connections

- Thick base plates for stability

- Corrosion-resistant finishes for longevity

Reliable Locking Mechanisms

The locking system is the heart of any jack stand. Look for:

- Multiple engagement points for redundancy

- Positive locking that requires deliberate action to release

- Visual confirmation of proper engagement

- Smooth operation without binding or sticking

Stability Features

A stable jack stand won’t tip or shift under load:

- Wide base design for lower center of gravity

- Non-slip feet or base pads

- Proper height-to-base ratio (typically 3:1 or less)

- Balanced weight distribution

Quality Certifications

Reputable manufacturers test their products to industry standards:

- ASME PALD (American Society of Mechanical Engineers)

- ANSI (American National Standards Institute) ratings

- SAE (Society of Automotive Engineers) compliance

- Third-party testing verification

Top Jack Stand Brands and Models for 2025

The market offers numerous options, but some brands consistently deliver superior quality and reliability. Here are the standout performers:

The market offers numerous options, but some brands consistently deliver superior quality and reliability. Here are the standout performers:

Premium Tier: Professional-Grade Options

Esco 10498 Jack Stands (3-Ton) These stands represent the gold standard for serious mechanics. Features include:

- Forged steel construction for maximum strength

- Self-locking ratchet mechanism with 13 locking positions

- Extra-wide base (7.5″ x 7.5″) for exceptional stability

- Height range: 11.25″ to 16.75″

AC Hydraulic DL20-2 (2-Ton) Danish engineering meets practical design:

- TÜV-certified European safety standards

- Unique saddle design fits various lift points

- Compact storage with nested design

- Lifetime warranty against manufacturing defects

Mid-Range: Best Value Options

Craftsman 4-Ton Jack Stands (Set of 2) Excellent balance of price and performance:

- Heavy-duty steel construction with powder coating

- Pin-style locking with 6 height positions

- Large base plates for enhanced stability

- Height range: 12″ to 18″

JEGS 80067 (3-Ton) Popular among DIY enthusiasts:

- Welded steel construction with reinforced base

- Quick-adjust ratcheting mechanism

- Safety lock pin for extra security

- Competitive pricing without compromising quality

Budget-Friendly: Entry-Level Options

Torin Big Red T43002A (3-Ton) Solid performance at an affordable price:

- Cast steel construction with welded base

- Double-locking ratchet teeth

- Wide pyramid base for stability

- Height range: 11.25″ to 16.75″

Performance Tool W41023 (2-Ton) Basic but reliable for light-duty use:

- Steel construction with rust-resistant finish

- Pin-style adjustment with 5 positions

- Compact design for easy storage

- Budget-friendly option for occasional use

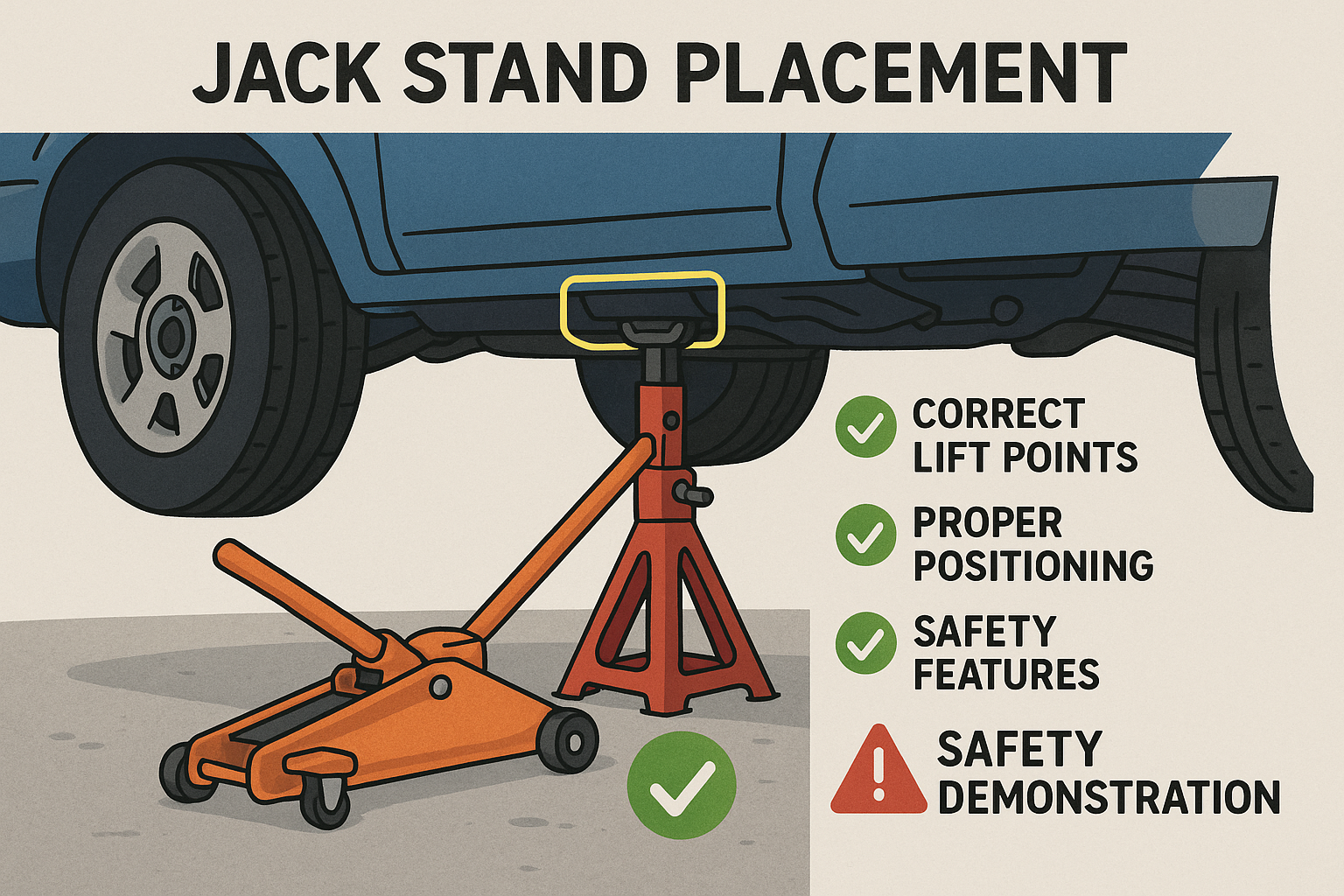

Proper Jack Stand Setup and Safety Procedures

Knowing how to properly use your car on jack stand setup is just as important as buying quality equipment. Follow these step-by-step procedures for maximum safety:

Pre-Setup Safety Checklist

Before you even touch your jack, complete this essential checklist:

- ✅ Park on level, solid ground (concrete or asphalt, never gravel or dirt)

- ✅ Engage parking brake and put automatic transmissions in Park

- ✅ Turn off engine and remove keys

- ✅ Chock wheels that will remain on the ground

- ✅ Locate proper lift points in your owner’s manual

- ✅ Inspect jack and stands for damage or wear

Step-by-Step Lifting Procedure

Step 1: Position Your Floor Jack Place the floor jack under the designated lift point. Most vehicles have reinforced areas specifically designed for jacking, typically:

- Pinch welds along the frame rails

- Subframe mounting points

- Differential housing (rear axle)

- Engine crossmember (front end)

Step 2: Initial Lift Slowly raise the vehicle just enough to take weight off the wheels. Stop and double-check that:

- Jack is properly positioned and stable

- Vehicle isn’t shifting or binding

- Lift point is making solid contact

Step 3: Position Jack Stands While the vehicle is still supported by the floor jack:

- Place jack stands under appropriate support points

- Adjust height so stands just contact the vehicle

- Ensure stands are plumb and stable

Step 4: Transfer Weight Slowly lower the floor jack until the vehicle’s full weight rests on the jack stands. The jack should still be in position but not supporting weight. Step 5: Final Safety Check Before getting under the vehicle:

- Gently shake the car to ensure stability

- Verify jack stands are properly locked

- Keep the floor jack in position as backup

- Never rely on a single point of support

Common Setup Mistakes to Avoid

Even experienced mechanics sometimes make these dangerous errors: ❌ Using Only One Jack Stand Always use pairs of stands when lifting an entire axle. Single-point support is inherently unstable and dangerous. ❌ Mixing Different Stand Heights Using stands of different heights can create stress points and instability. Match your stands for even support. ❌ Positioning on Soft Ground Jack stands can sink into soft surfaces under load. Always use solid, level ground or place stands on large boards for additional support. ❌ Ignoring Weight Limits Don’t assume your stands can handle any vehicle. Check actual vehicle weight against stand ratings, including any modifications or cargo. ❌ Rushing the Process Take your time with setup. Most jack stand accidents happen when people skip safety steps to save a few minutes.

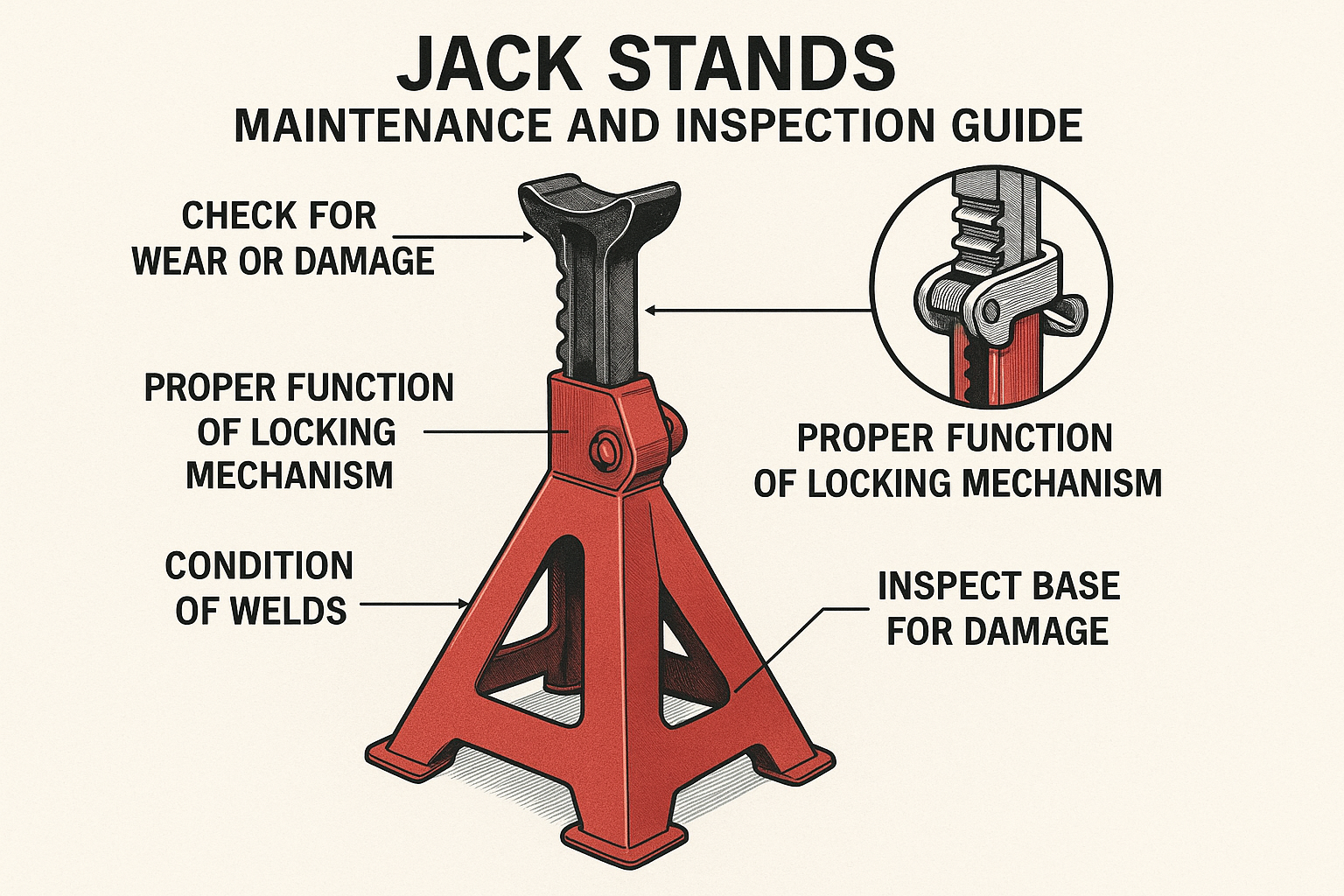

Maintenance and Inspection of Jack Stands

Like any safety equipment, automotive jack stands require regular maintenance to ensure reliable operation. A few minutes of inspection before each use can prevent catastrophic failure.

Like any safety equipment, automotive jack stands require regular maintenance to ensure reliable operation. A few minutes of inspection before each use can prevent catastrophic failure.

Pre-Use Inspection Checklist

Before every use, examine your stands for these potential issues: Structural Integrity

- Cracks in welds or base metal

- Bent or deformed components

- Corrosion or rust that weakens the structure

- Loose or missing hardware

Locking Mechanism

- Smooth operation of ratchets or pins

- Proper engagement without binding

- Wear on locking surfaces that could cause slippage

- Spring tension on safety locks

Base and Contact Points

- Flat, stable base without warping

- Clean contact surfaces free of oil or debris

- Intact saddle padding if equipped

- Non-slip feet properly attached

Cleaning and Storage Best Practices

Proper care extends the life of your stands and maintains their safety: Regular Cleaning

- Remove oil and grease that can cause slipping

- Wire brush rust spots and apply protective coating

- Lubricate moving parts with appropriate grease

- Store in dry location to prevent corrosion

Proper Storage

- Fully retract adjustable components

- Store indoors when possible

- Avoid stacking heavy items on stands

- Keep matching pairs together

When to Replace Jack Stands

Sometimes repair isn’t enough, and replacement becomes necessary for safety: Immediate Replacement Required

- Any cracks in structural components

- Bent support posts that won’t straighten

- Failed locking mechanisms that won’t hold

- Significant corrosion affecting strength

Consider Replacement

- Excessive wear on locking surfaces

- Repeated binding in adjustment mechanisms

- Age-related deterioration (10+ years)

- Unknown history of used stands

Remember, jack stands are safety equipment where failure means potential injury or death. When in doubt, replace them – your life is worth more than the cost of new stands.

Jack Stands vs. Other Lifting Methods

Understanding when to use jack stands versus other lifting methods helps you choose the right tool for each job. Each method has its place in automotive maintenance.

Jack Stands vs. Floor Jacks

While floor jacks and jack stands often work together, they serve different purposes: Floor Jacks (Hydraulic)

- Quick lifting for tire changes

- Precise positioning during installation

- Higher lifting capacity for initial lift

- ❌ Not safe for extended support due to potential hydraulic failure

Jack Stands

- Stable long-term support for extended work

- Mechanical locking won’t fail like hydraulics

- Multiple stands for complete vehicle support

- ❌ Slower to position than hydraulic jacks

Best Practice: Use floor jacks to lift, jack stands to support. Never work under a vehicle supported only by a hydraulic jack.

Jack Stands vs. Vehicle Ramps

Car ramps offer an alternative for some maintenance tasks: Ramps Advantages

- Quick setup for oil changes

- Drive-on convenience

- Stable platform for extended work

- No lifting required

Jack Stands Advantages

- Individual wheel removal capability

- Access to suspension components

- Variable height adjustment

- Work on any lift point

When to Use Each: Choose ramps for simple maintenance like oil changes where wheels stay on. Use jack stands when you need wheel removal or suspension access.

Professional Lifts vs. Jack Stands

For serious enthusiasts, understanding lift options helps with garage planning: Two-Post Lifts

- Full vehicle access underneath

- Professional-grade stability

- Quick operation for frequent use

- ❌ High cost and installation requirements

Four-Post Lifts

- Drive-on convenience like ramps

- Storage capability for multiple vehicles

- Excellent stability

- ❌ Limited access for some repairs

Jack Stands

- Affordable entry point for DIY mechanics

- Portable and flexible positioning

- No installation required

- Perfect for occasional use

Troubleshooting Common Jack Stand Issues

Even quality jack stands can develop problems over time. Knowing how to identify and address common issues keeps your equipment safe and functional.

Even quality jack stands can develop problems over time. Knowing how to identify and address common issues keeps your equipment safe and functional.

Sticking or Binding Adjustments

When your stands become difficult to adjust: Causes

- Dirt and debris in adjustment mechanisms

- Corrosion on sliding surfaces

- Bent components from improper use

- Lack of lubrication

Solutions

- Clean thoroughly with degreaser and wire brush

- Apply penetrating oil to stuck components

- Lubricate with appropriate grease after cleaning

- Replace if bent components can’t be straightened

Locking Mechanism Problems

Locks that don’t engage properly are extremely dangerous: Warning Signs

- Partial engagement of locking pins

- Slipping under load during use

- Difficulty releasing locks when adjusting

- Visible wear on locking surfaces

Immediate Actions

- Stop using immediately if locks don’t fully engage

- Inspect for wear on all locking surfaces

- Test mechanism without load before use

- Replace stands if locks are compromised

Stability Issues

Unstable stands create dangerous working conditions: Common Causes

- Uneven ground beneath stands

- Improper positioning on vehicle

- Mismatched stand heights

- Overloading beyond rated capacity

Prevention

- Always use level, solid surfaces

- Position on designated lift points

- Use matching pairs of stands

- Verify weight ratings before use

Cost Analysis: Investment vs. Safety

Understanding the true cost of jack stands helps put their importance in perspective. Like proper tire maintenance, investing in quality safety equipment pays dividends over time.

Initial Investment Breakdown

Budget Options ($30-60 per pair)

- Basic functionality for occasional use

- Limited warranty coverage

- Standard safety features

- Suitable for light vehicles and simple maintenance

Mid-Range Options ($60-120 per pair)

- Enhanced durability and features

- Better warranties and support

- Professional-grade construction

- Ideal for regular DIY mechanics

Premium Options ($120-300+ per pair)

- Maximum safety margins and features

- Commercial-grade construction

- Extended warranties and certifications

- Perfect for professional use or heavy vehicles

Long-Term Value Considerations

Quality jack stands offer excellent long-term value: Durability Benefits

- Decades of service with proper care

- Consistent performance over time

- Reduced replacement costs

- Better resale value

Safety ROI

- Accident prevention saves medical costs

- Confidence enables more DIY maintenance

- Insurance against catastrophic failure

- Peace of mind during every use

Maintenance Savings

- Enables DIY repairs that save labor costs

- Proper tire rotation extends tire life

- Regular maintenance prevents costly breakdowns

- Self-sufficiency reduces shop visits

Cost of Accidents

The true cost of inadequate equipment becomes clear when you consider accident scenarios: Medical Costs

- Emergency room visits: $1,000-5,000+

- Surgery and treatment: $10,000-100,000+

- Long-term care: Potentially unlimited

- Lost income during recovery

Vehicle Damage

- Crushed body panels: $2,000-10,000+

- Suspension damage: $1,000-5,000+

- Frame damage: $5,000-15,000+

- Total loss in severe cases

When viewed this way, even premium jack stands represent an incredibly small investment for the protection they provide.

Advanced Tips for Professional Results

Taking your jack stand skills to the next level involves understanding advanced techniques used by professional mechanics.

Multi-Point Support Strategies

For complex repairs requiring access to multiple areas: Four-Corner Support

- Lift entire vehicle for comprehensive access

- Use four matching stands for even support

- Position at frame rails or subframe points

- Ideal for transmission or exhaust work

Three-Point Support

- Front and one rear corner for brake work

- Rear and one front corner for differential service

- Provides stability while maintaining access

- Useful when space is limited

Rolling Support

- Combine stands with rolling jacks for positioning

- Allows fine adjustment during installation

- Professional technique for precision work

- Requires experience and careful coordination

Working with Modified Vehicles

Lowered cars, lifted trucks, and modified vehicles present unique challenges: Lowered Vehicles

- Low-profile stands may be necessary

- Extended reach might be required

- Frame reinforcement considerations

- Clearance issues with body kits

Lifted Vehicles

- Higher capacity stands often needed

- Extended height range requirements

- Stability concerns with higher center of gravity

- Access challenges due to increased height

Modified Suspensions

- Non-standard lift points may be present

- Weight distribution changes affect planning

- Aftermarket components may interfere with placement

- Consult modification documentation for guidance

Professional Shortcuts (That Are Actually Safe)

Experienced mechanics develop efficient techniques that maintain safety: Pre-Positioning

- Set up multiple stands before lifting

- Organize tools within easy reach

- Plan work sequence to minimize repositioning

- Have helper for complex procedures

Quick-Change Techniques

- Leave stands in position for repeated access

- Use secondary support when adjusting

- Master one-person setup procedures

- Develop muscle memory for common positions

Environmental and Storage Considerations

Proper storage and environmental protection extend the life of your investment and ensure reliable performance.

Climate Protection

Different climates present unique challenges for jack stand maintenance: Humid Environments

- Increased corrosion risk requires vigilant maintenance

- Regular cleaning and protective coatings

- Indoor storage when possible

- Desiccant packs in storage containers

Cold Climates

- Road salt exposure accelerates corrosion

- Thermal cycling can affect metal properties

- Lubrication may thicken in extreme cold

- Pre-warming in heated spaces before use

Hot, Dry Climates

- UV exposure can degrade rubber components

- Thermal expansion affects metal dimensions

- Dust accumulation in mechanisms

- Shade storage prevents overheating

Garage Organization

Efficient storage keeps stands accessible and protected: Wall-Mounted Storage

- Vertical hanging saves floor space

- Easy access for frequent use

- Visual inspection during storage

- Prevents damage from floor hazards

Mobile Storage Carts

- Wheels enable easy positioning

- Integrated tool storage

- Weather protection with covers

- Professional appearance in organized garages

Dedicated Storage Areas

- Climate-controlled environments ideal

- Away from corrosive chemicals

- Easy access without moving other items

- Inventory tracking for multiple sets

Future of Jack Stand Technology

The automotive industry continues evolving, and jack stand technology advances to meet new challenges.

Material Innovations

Modern manufacturing techniques enable improved designs: Advanced Alloys

- Higher strength-to-weight ratios

- Improved corrosion resistance

- Better fatigue properties

- Cost-effective production

Composite Materials

- Lightweight alternatives for portable use

- Corrosion immunity in harsh environments

- Vibration damping properties

- Specialized applications in racing

Smart Safety Features

Technology integration enhances safety and usability: Load Monitoring

- Electronic sensors detect overloading

- Visual and audible warnings

- Data logging for maintenance tracking

- Smartphone integration for monitoring

Automated Positioning

- Self-leveling mechanisms

- Motorized adjustment for precision

- Remote control operation

- Integration with lifting systems

Electric Vehicle Considerations

The rise of electric vehicles brings new requirements: Battery Pack Protection

- Specialized lift points avoid battery damage

- Insulation requirements for electrical safety

- Weight distribution changes with battery placement

- Manufacturer-specific procedures and equipment

High Voltage Safety

- Isolation procedures before lifting

- Specialized training requirements

- Emergency disconnect protocols

- Professional equipment for safety compliance

As vehicles continue evolving, jack stand technology will adapt to meet new safety and performance requirements while maintaining the fundamental principles of secure mechanical support.

Conclusion

Investing in quality jack stands isn’t just about having the right tools – it’s about protecting your most valuable asset: your life. Whether you’re a weekend warrior changing brake pads or a daily driver rotating tires, the right jack stand setup provides the foundation for safe, confident automotive maintenance. Remember these key principles: always choose stands rated well above your vehicle’s weight, never work under a car supported only by a hydraulic jack, and inspect your equipment before every use. Quality automotive jack stands from reputable manufacturers offer decades of reliable service when properly maintained and used according to safety procedures. The small investment in proper car jack stands pays enormous dividends in safety, capability, and peace of mind. Don’t let inadequate equipment put you at risk – your family needs you to come out from under that car in one piece. Ready to upgrade your garage safety? Start by calculating your vehicle’s requirements using our safety calculator above, then invest in quality stands that will serve you reliably for years to come. Your future self will thank you for making safety the top priority. For more automotive maintenance guidance and safety tips, explore our comprehensive tire and automotive guides to keep your vehicle running safely and efficiently.