When it comes to maintaining commercial trucks and semis, having the right lug nut tools isn’t just about convenience—it’s a critical safety requirement. The high torque demands of heavy-duty vehicles require specialized equipment that can handle forces far beyond what standard automotive tools can manage. In this comprehensive guide, we’ll explore the essential tools every truck owner, fleet manager, and mechanic needs for proper lug nut maintenance, from professional-grade torque wrenches to powerful multipliers and specialized impact tools.

Torque Requirements for Semi Trucks & Heavy Vehicles

Understanding the specific torque requirements for semi-truck lug nuts is the foundation of proper wheel maintenance. Unlike passenger vehicles, commercial trucks require significantly higher torque specifications to ensure wheel security under heavy loads and constant use.

Standard Torque Specifications: Most semi-truck lug nuts require between 450-600 ft-lbs of torque, depending on the specific vehicle make and model. Always consult your vehicle’s maintenance manual for exact specifications.

Comparing Vehicle Torque Requirements

| Vehicle Type | Typical Torque Range | Lug Nut Size | Recommended Tool |

| Passenger Car | 80-100 ft-lbs | 17-19mm | 1/2″ drive torque wrench |

| Light Truck/SUV | 100-150 ft-lbs | 19-22mm | 1/2″ heavy-duty torque wrench |

| Commercial Truck | 450-600 ft-lbs | 33mm (1-1/16″ to 1-1/2″) | 3/4″ or 1″ drive torque wrench |

| Semi Truck | 450-600 ft-lbs | 33mm (1-1/16″ to 1-1/2″) | 1″ drive torque wrench or multiplier |

Risks of Improper Torquing

Under-Torquing Risks:

- Wheel loosening during operation

- Potential wheel separation

- Stud and bolt hole damage

- Increased wear on wheel components

- Catastrophic safety hazards

Over-Torquing Risks:

- Stretched or broken studs

- Warped brake rotors

- Damaged wheel bearings

- Cracked wheel components

- Difficulty removing lug nuts later

Safety Warning: Always recheck torque after 50-100 miles of driving following any wheel service. Temperature changes and settling can cause torque values to shift.

Best Torque Wrenches for Semi Lug Nuts

A high-quality torque wrench is the most fundamental tool for properly securing lug nuts on semi trucks. These specialized wrenches allow you to apply the exact amount of torque specified by the manufacturer, ensuring optimal safety and performance.

Top Recommended Torque Wrenches for Semi Trucks

1. Proto J6016C 3/4-Inch Drive Torque Wrench

Specifications:

- Drive Size: 3/4-inch

- Torque Range: 150-750 ft-lbs

- Length: 42.5 inches

- Accuracy: ±3%

- Includes calibration certificate

The Proto J6016C offers professional-grade accuracy with its click-type mechanism that signals when you’ve reached the desired torque. Its extended length provides the leverage needed for high-torque applications, while the durable construction ensures years of reliable service.

2. Precision Instruments PREC3FR250F Split Beam Torque Wrench

Specifications:

- Drive Size: 3/4-inch

- Torque Range: 100-600 ft-lbs

- Length: 43 inches

- Accuracy: ±4%

- Split beam design (no need to reset to zero)

This split beam torque wrench eliminates the need to “reset to zero” after use, which helps maintain calibration longer. The innovative design provides consistent accuracy and the ergonomic grip reduces operator fatigue during extended use on multiple wheels.

Professional Tip: Torque Wrench Maintenance

Always store your torque wrench at its lowest setting (but not zero) to maintain spring tension and ensure long-term accuracy. Have your wrench calibrated annually if used regularly for commercial applications.

Torque Multipliers – What They Are & When to Use Them

Torque multipliers are mechanical devices that amplify the force applied to a fastener, allowing you to achieve high torque values with significantly less input force. For semi-truck applications where torque requirements often exceed 450 ft-lbs, these tools are invaluable for both applying and removing lug nuts.

How Torque Multipliers Work

Torque multipliers use planetary gear systems to increase the applied torque by a specific ratio—typically 4:1 or 5:1. This means that 100 ft-lbs of input force can generate 400-500 ft-lbs of output torque, making it possible to loosen or tighten lug nuts that would otherwise require pneumatic tools or excessive physical effort.

When to Use a Torque Multiplier:

- When dealing with severely overtightened lug nuts

- For roadside emergencies without access to air tools

- When precise torque application is required

- In situations where air compressors aren’t available

- When physical limitations make high-torque applications difficult

Types of Torque Multipliers:

- Manual multipliers (gear-based)

- Hydraulic multipliers (fluid pressure)

- Pneumatic multipliers (air-powered)

- Electric multipliers (battery-powered)

- Specialized lug nut multipliers

Top Recommended Torque Multipliers

1. Norwolf 4:1 Torque Multiplier Set

Specifications:

- Multiplication Ratio: 4:1

- Maximum Output Torque: 2,200 ft-lbs

- Input Drive: 1/2-inch

- Output Drive: 3/4-inch

- Includes: Reaction bar, extension, and 4 impact sockets

The Norwolf multiplier set provides everything needed for truck lug nut service. The reaction bar prevents kickback during operation, making it safer and easier to use. The included sockets cover common semi-truck lug nut sizes, providing a complete solution in one package.

2. AME International Nut Buddy Torque Multiplier

Specifications:

- Specialized design for stuck lug nuts

- Compact size for easy storage

- Works with standard breaker bars

- No reaction bar needed

- Compatible with most truck wheel patterns

Unlike traditional multipliers, the Nut Buddy uses the adjacent wheel stud as a leverage point to break loose even the most stubborn lug nuts. Its compact design makes it perfect for roadside emergencies, and at around $100, it’s a cost-effective solution that can save hundreds in roadside assistance fees.

Pro Tip: When using a torque multiplier, always secure the reaction arm against a solid, immovable object. Never use your hand to hold the reaction arm, as this can result in serious injury when the multiplier engages.

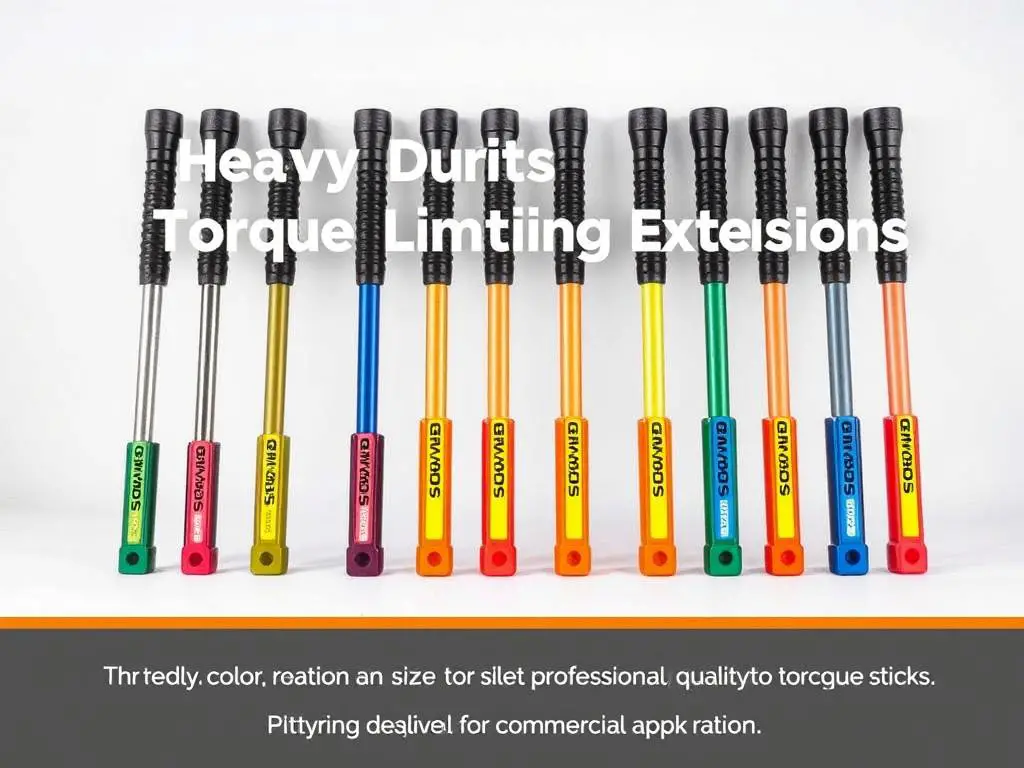

Using a Torque Stick with an Impact Wrench

Torque sticks (also called torque limiting extensions) are specialized tools designed to work with impact wrenches to prevent over-torquing. They act as a mechanical torque limiter by flexing and absorbing excess energy once the desired torque level is reached.

How Torque Sticks Work with Impact Wrenches

Torque sticks are designed to flex and absorb energy from the impact wrench once a specific torque value is reached. While not as precise as a calibrated torque wrench, they provide a reliable way to prevent over-torquing when using high-powered impact tools.

Benefits of Using Torque Sticks:

- Prevents over-torquing with impact wrenches

- Speeds up wheel service operations

- Reduces risk of damaged wheel components

- Color-coded for easy torque identification

- Works with standard impact wrenches

Limitations to Consider:

- Less precise than torque wrenches

- Requires final torque verification

- Performance affected by air pressure variations

- Limited availability for very high torque values

- Requires proper impact wrench sizing

Recommended Impact Wrenches for Semi Truck Lug Nuts

1. Ingersoll Rand 2141 3/4-Inch Impact Wrench

Specifications:

- Drive Size: 3/4-inch

- Maximum Torque: 1,200 ft-lbs

- Air Consumption: 6.0 CFM

- Weight: 7.4 lbs

- Titanium hammer case for durability

As recommended by professional truckers, the IR 2141 delivers exceptional power while using less air than comparable models. The titanium hammer case provides durability while the ergonomic grip reduces operator fatigue. This model is specifically mentioned by truckers as ideal for on-road use with truck air systems.

Recommended Torque Sticks for Semi Trucks

OEMTOOLS Heavy Duty Torque Limiting Extensions

Specifications:

- Drive Size: 1/2-inch to 3/4-inch adapters included

- Torque Ranges: 350, 400, 450, 500, and 550 ft-lbs

- Color-coded for easy identification

- Chrome molybdenum steel construction

- Compatible with all standard impact wrenches

This comprehensive set includes torque sticks calibrated for common semi-truck torque specifications. The color-coding system makes it easy to select the right extension for your specific vehicle requirements, while the included adapters ensure compatibility with different impact wrench drive sizes.

Important Safety Note: While torque sticks provide convenience, always follow up with a properly calibrated torque wrench to verify the exact torque specification has been achieved. This two-step process ensures maximum safety and compliance with manufacturer requirements.

Frequently Asked Questions About Heavy-Duty Lug Nut Tools

How much torque do semi lug nuts need?

Most semi-truck lug nuts require between 450-600 ft-lbs of torque, depending on the specific vehicle make and model. Always consult your vehicle’s maintenance manual for the exact specifications. Using the correct torque is critical for safety and preventing wheel-off incidents.

Can I use a car torque wrench on a truck?

Standard automotive torque wrenches typically max out at 150-250 ft-lbs, which is insufficient for semi-truck lug nuts that require 450-600 ft-lbs. Using an undersized torque wrench can damage the tool and result in dangerously under-torqued fasteners. Always use a properly sized 3/4″ or 1″ drive torque wrench rated for the required torque values.

How often should I calibrate my torque wrench?

For commercial applications, torque wrenches should be calibrated at least annually or after approximately 5,000 cycles. If the wrench is dropped or subjected to excessive force, immediate recalibration is recommended. Many professional shops maintain calibration records as part of their quality assurance and liability protection programs.

What size air hose should I use with my impact wrench?

For 3/4″ and 1″ impact wrenches used on semi-truck lug nuts, a minimum 1/2″ inner diameter air hose is recommended. Using a smaller 3/8″ hose will restrict airflow and significantly reduce the tool’s performance. Additionally, ensure your air fittings and connectors are also properly sized to prevent bottlenecks in the air supply system.

Conclusion: Investing in the Right Heavy-Duty Lug Nut Tools

Proper maintenance of semi-truck lug nuts is not just about convenience—it’s a critical safety requirement that protects lives and property on the road. Investing in high-quality, purpose-built tools designed specifically for heavy-duty applications ensures that you can perform this essential maintenance correctly and efficiently.

Whether you’re a professional fleet manager responsible for dozens of vehicles or an owner-operator maintaining your own rig, having the right combination of torque wrenches, multipliers, and impact tools will save you time, money, and potentially prevent dangerous wheel-off incidents.

Essential Heavy-Duty Lug Nut Tool Kit

Build your complete professional toolkit with these essential heavy-duty lug nut tools. Proper equipment ensures safety and compliance with manufacturer specifications.